Here at Anderson Innovations, our focus is always to improve the machine operator’s experience by designing the tools they need to get the job done. When designing products, our goal is to create a solution to the problems found on job sites. One of those problems has to do with the self-scoring blade.

If you have ever used one, you will have noticed that the radius where the wings bend up at either end gets dull much faster than the rest of the blade. Many operators keep running on a dull blade instead of taking the time to re-sharpen it. We have been guilty of this as well. While it’s possible to get away with running a dull flat blade for a little while. However, when the radius of a self-scoring blade gets dull, the job becomes much more difficult as it tears the material instead of cutting through it. We wanted to solve this problem, and our answer is the Hook Blade.

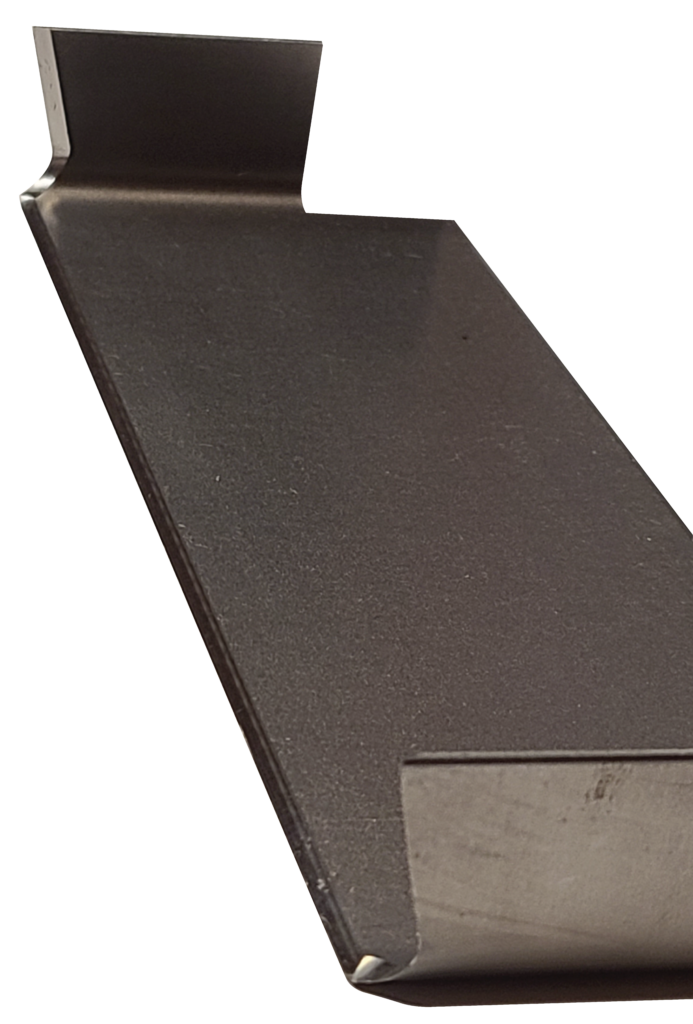

The Hook Blade is our patented self-scoring blade design that can be recognized by the “hook” in the radius between the main portion of the scraper blade and the vertical wings. The hook design provides more cutting surface in this area of the blade. With more surface, the cutting edge lasts longer, and you can take up more material than with a standard self-scoring blade. This allows you to:

The Hook Blade can be used on any material that you would typically use a self-scoring blade to remove. Not sure which blade or machine is best for your project? Here are a few points to consider based on the jobs that you’re working on:

For larger jobs, we recommend one of our Ride-On Floor Scrapers. Depending on the type of material you’re taking up, here’s what you should use for blades:

Depending on the machine’s weight, you may be able to utilize our lighter .062” thick blades. A thinner blade will typically do a better job scraping the material, and due to the smaller cross-section, it’s easier for the machine to push through adhesive. However, if the ride-on machine is too heavy, it will bend the blade, which is why we typically recommend that you use our heavy-duty .094” thick blade for riders.

For smaller jobs or smaller spaces, we recommend using a Walk-Behind Floor Scrapers, or a smaller/more compact Ride-On Floor Scraper such as the ES 1300 or the ES 1000. Depending on the type of material you’re taking up, here’s what you should use:

For more information on our blades and their uses, please reference the chart at the bottom of this page.

Are you interested in purchasing blades, a Floor Scraper or in becoming a distributor of Anderson Innovations machines? Contact us to get started! Our line of blades will be available to purchase from us directly beginning mid-September, 2024